Facility Safety: How to Secure Pallet Drop Areas with Overhead Hoists

Many manufacturing facilities - especially chemical companies and food processing plants – use overhead hoists to lift material up to an elevated work platform instead of using a lift truck. This is the traditional method of lifting super sacks up to the processing platform where they can be dumped into hoppers. Other facilities may use a traditional lift truck to lift the material up, but then will use an overhead hoist to access the material once they are on the platform. This is a common method of emptying drums of ingredients off of a pallet.

Both of these areas typically create environments where employees are working around the ledges of these elevated platforms. In these scenarios a proactive guarding solution should be installed.

When you are looking to secure these areas, it’s important to keep these things in mind:

If the operation requires overhead access then the safety device must be designed to integrate with the machinery that is being used: for instance, integration with an overhead crane used to lift super sacks up to the platform, or a vacuum hoist that is used to unload material off of a pallet. This means that the safety device in place cannot interfere with this operation so the safety gate shouldn’t have any overhead mechanics. Instead it needs to provide a clear path to move the material through this area.

If the operation requires overhead access is this required at both the ledge and above the pallet drop area? If a forklift is lifting material up to the ledge and a hoist is being used to unload the material then the overhead access is only needed on the operator’s side.

Do the employees have access to the pallet drop area? If so the area in which they are working must feature a safe environment at all times. This means all ledges on elevated areas in which they are walking and working must be protected.

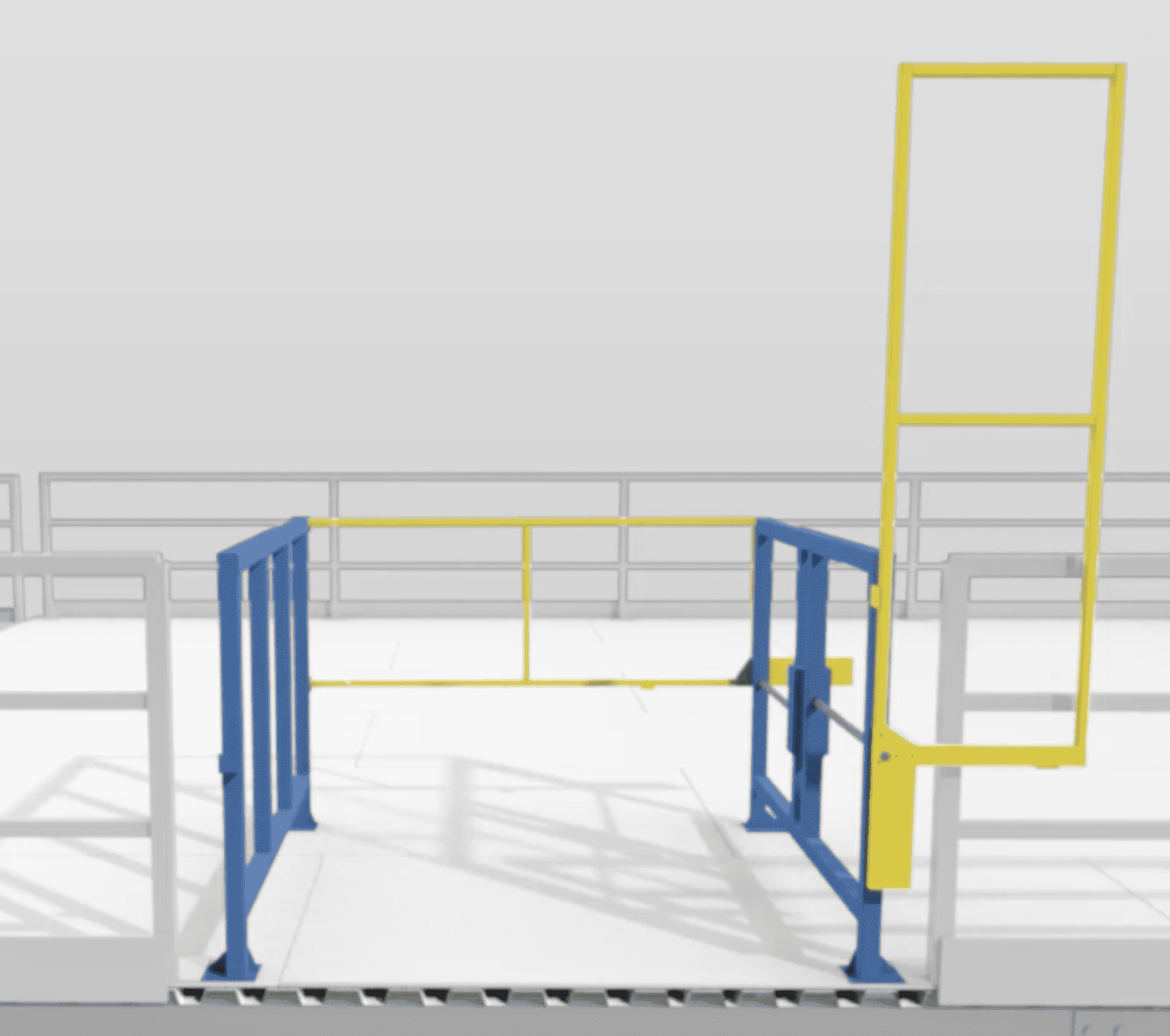

Our Open Top Safety Gate is ideal for securing these areas. This dual-gate system protects workers on elevated areas; when the ledge-gate is open, allowing material to be delivered or loaded, the rear-side gate is closed, protecting workers from falling off the ledge. When the rear-side gate is raised to access the pallet, the ledge-side gate closes. The gates are interconnected off to the side with no overhead mechanics, which creates a safe work environment without restricting the access overhead.

This solution is also ideal when tall pallets are being loaded up to the area. The same concept of keeping the overhead access applies so these tall pallets can be moved through the area.

We’ve created a video that shows how our Open Top Safety Gate works, which you can view here.